Looking at the Many Uses of Nickel

Nickel is a silvery-white metal that is used mainly to make stainless steel and nickel-based alloy. Nickel makes alloys stronger and better-able to withstand extreme temperatures and corrosive environments. When some percentage of nickel is added to steel it is called Nickel Steel and it is the most important among all the steel alloys due to its use in various places all around the world.

Nickel was first identified as a unique element in 1751 by Baron Axel Fredrik Cronstedt, a Swedish mineralogist and chemist. He originally called the element kupfernickel because it was found in rock that looked like copper (kupfer) ore and because miners thought that "bad spirits" (nickel) in the rock were making it difficult for them to extract copper from it.

Nickel is a naturally-occurring metallic element with a silvery-white, shiny appearance. It is the fifth-most common element on earth and occurs extensively in the earth’s crust and core. Nickel, along with iron, is also a common element in meteorites and can even be found in small quantities in plants, animals and seawater. While the concentration of nickel in the earth's crust is 80 parts per million, the earth's core consists mainly of a nickel-iron alloy. Nickel is the fifth-most common element on earth. Nickel is a hard, malleable, and ductile metal. Nickel properties make it a good conductor of heat and electricity and it has a melting point is 1453°C and boiling point is 2913 °C.

Nickel is typically found in two types of deposits: laterite deposits, which are the result of intensive weathering of surface nickel-rich rocks, and magmatic sulfide deposits. Nickel can also be found in manganese nodules and crusts on the deep sea floor, but currently these are not being mined, according to Geology.com. The main mineral sources of nickel ore are limonite, garnierite and pentlandite.

Few things are made of pure nickel. Instead, nickel tends to play a supportive and stabilizing role in industry materials; it is usually combined with other metals to produce stronger, shinier and more durable products through nickel-based alloys. Nickel is commonly used as a protective outer coating for softer metals.

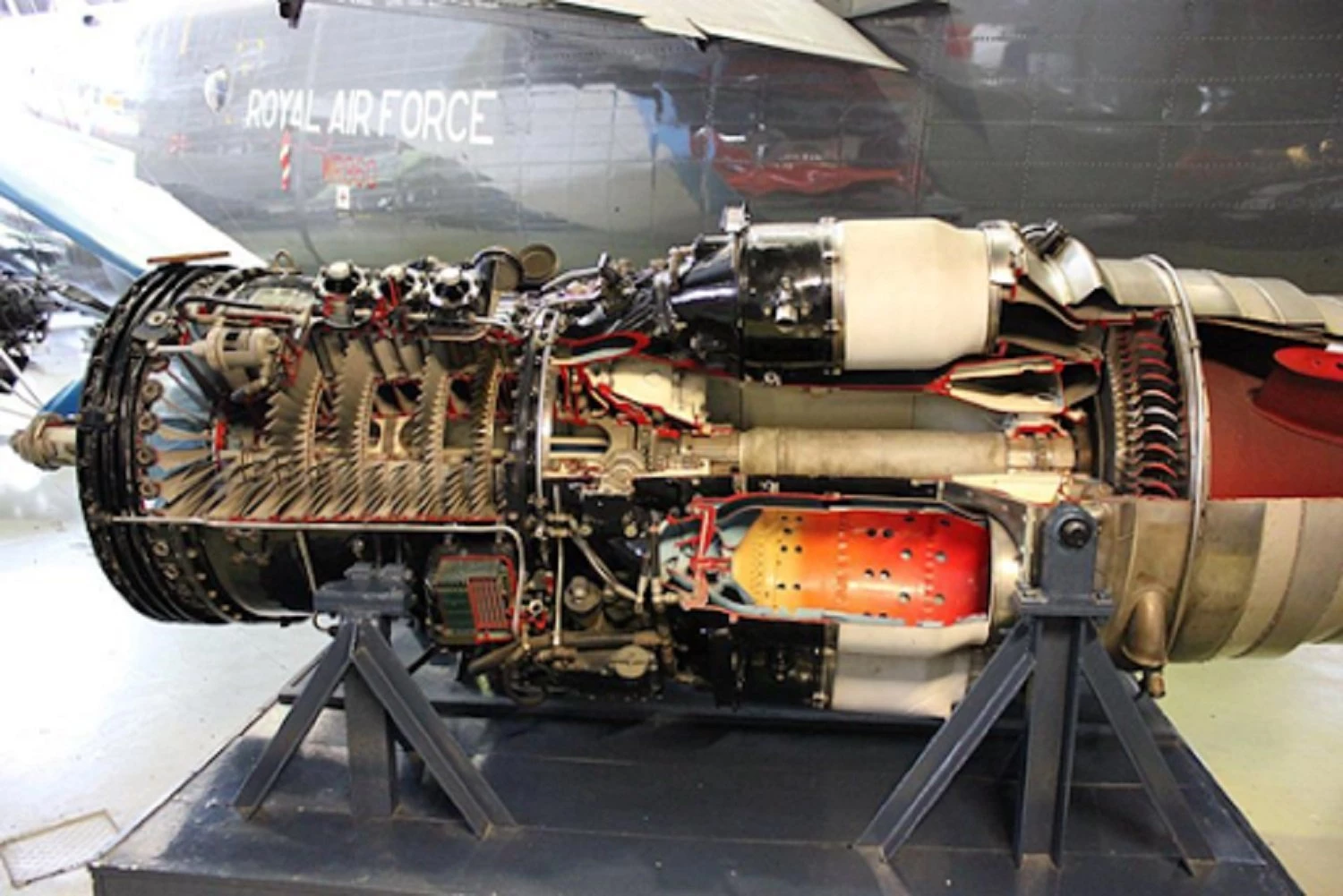

Historically, the most common and crucial use of nickel is in the manufacturing of monetary coins; in fact the US 5-cent coin is commonly called the “nickel” and it is a 25% nickel-based alloy. Nickel is also used in making wires and it is used to make a variety of nickel-based alloys which are further used to make armour plating, nails, or pipes. It is used in gas turbines and rocket engines as nickel properties give the capability to resist corrosion even at high temperature. Monel (a nickel-based alloy of nickel and copper), is a hard compound and can resist corrosion by seawater so it is used in the propeller shaft in boats and in desalination plants.

Nitinol is a nickel-based alloy that remembers its previous shape. According to Chemicool.com if you heat a wire of this nickel-titanium alloy at 500°C; you can bend the wire into any shape you'd like. Allow it to cool and bend it into another shape. Then reheat the wire — and watch the first shape reappear.

Modern technology has greatly innovated the use of nickel. Construction and manufacturing, for one has used forms of nickel-based alloys in cladding, structural work, and other uses.

One of the most exciting uses of nickel has been in the development of batteries. Nickel (Ni) has long been widely used in batteries, most commonly in nickel cadmium (NiCd) and in the longer-lasting nickel metal hydride (NiMH) rechargeable batteries, which came to the fore in the 1980s. Their adoption in power tools and early digital cameras revealed the potential for portable devices, changing expectations of how we work and live. The mid-1990s saw the first significant use of NiMH batteries in vehicles in the Toyota Prius. Around the same time, the first commercial applications for Li-ion batteries emerged, initially in camcorders and eventually finding their way into smartphones, laptops and the numerous other portable devices we now take for granted.

The major advantage of the use of nickel in batteries is that it helps deliver higher energy density and greater storage capacity at a lower cost. Further advances in nickel-containing battery technology mean it is set for an increasing role in energy storage systems, helping make the cost of each kWh of battery storage more competitive. Nickel batteries are making energy production from intermittent renewable energy sources such as wind and solar replace fossil fuels more viable.

In tandem with this increasing market share, nickel battery technology is also advancing, another reason why the proportion of nickel-containing Li-ion batteries in use is set to grow. Two of the most commonly-used types of batteries, Nickel Cobalt Aluminium (NCA) and Nickel Manganese Cobalt (NMC) have 80% and 33% use of nickel respectively; newer formulations of NMC are also approaching 80% nickel. Most Li-ion batteries now rely on nickel.

To find out more about Hallmark Mining Corporation, a nickel mining company in the Philippines, visit our website.

Sources: livescience.com, chemicool.com, rsc.org, nickelinstitute.org, smithsonian magazine, geology.com, philippinenickel.org